Grouting operations are performed to fill voids, as between tiles and under structural columns and machine bases.

The injection of grout is to stabilize dams or mass fills, or to reinforce and strengthen decaying walls and foundations, or to fill faults and crevices in rockformations.

Commonly Used Methods

When drilling grout holes, rotary drilling and percussive drilling are the most commonly used methods. In tunnels, gallery grouting is made in a fan pattern to strengthen the lining of the excavation.

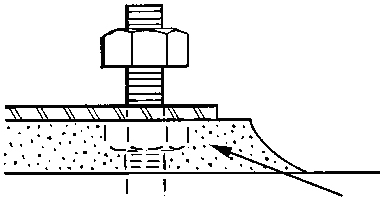

Jet grouting is a method to reinforce the ground by pumping in a cement paste into the soil at high pressure, with purpose to build either cement columns or totally consolidate the formations.

Jet Grouting Drilling Rig

Jet grouting drilling rig, also known as rotary spray rig, is a kind of drilling tool which can guarantee continuous dynamic property and static property under the condition of high pressure of work. It is used for conveying slurry, compressed air and water, etc. The rotary spray rig is composed of the drill pipe, shunt, drill bit, preventing loose machine, preventing loose device, padding fork and change-diametric joint. This jet grouting drilling rig includes low pipe type, crawler type, and high type.